Perfection in every detail

The Turning & Milling Experts

Then simply place your order and receive your parts right on time

– MADE IN GERMANY!

Turning Parts at a Glance

Production up to Ø 75mm – fully automated with bar feeders

Chuck parts manufacturing – fully automated with robotic loading

CNC-controlled machines – with 1 or 2 spindles

CNC-controlled sliding head machine

CNC-controlled turning-milling center – from Mazak

Manufacturing in all common materials – including free-cutting steel, stainless steel, structural steel, aluminum, brass, and plastics (mainly POM)

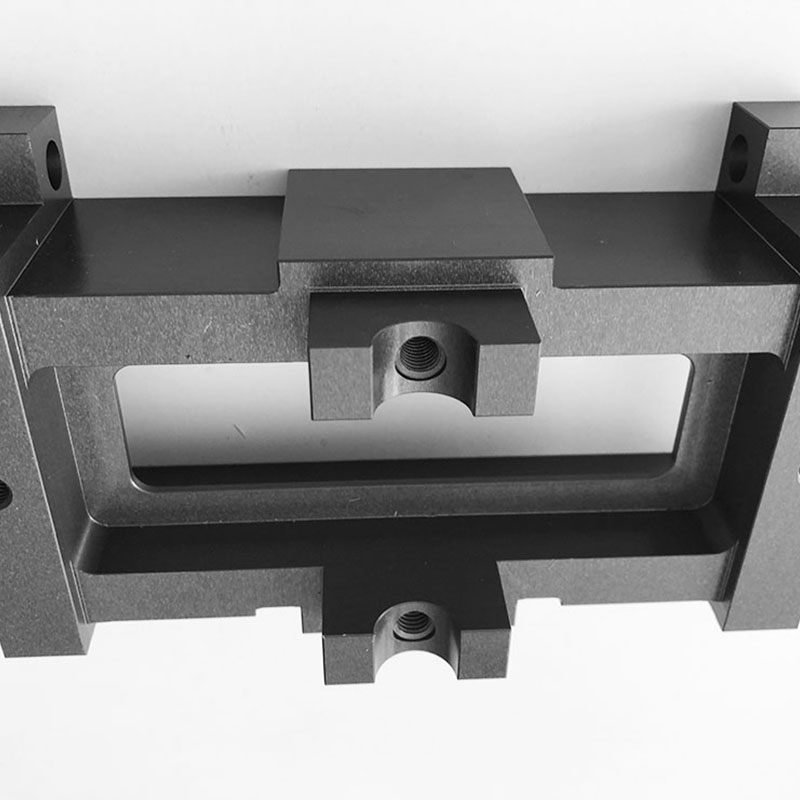

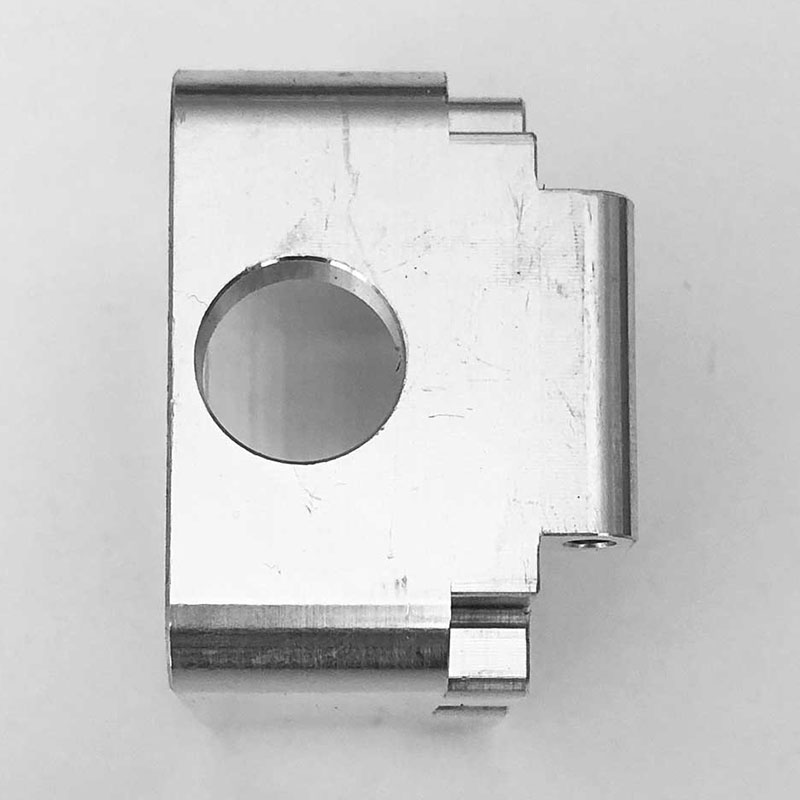

Milling Parts at a Glance

Production up to approx. 200mm x 200mm x 200mm

CNC-controlled 3-axis machining center

CNC-controlled 5-axis machining center

Manufacturing in all common materials – including free-cutting steel, stainless steel, structural steel, aluminum, brass, and plastics (mainly POM)

Turning Parts at a Glance

Production up to Ø 75mm – fully automated with bar feeders

Chuck parts manufacturing – fully automated with robotic loading

CNC-controlled machines – with 1 or 2 spindles

CNC-controlled sliding head machine

NC-controlled turning-milling center – from Mazak

Manufacturing in all common materials – including free-cutting steel, stainless steel, structural steel, aluminum, brass, and plastics (mainly POM)

Milling Parts at a Glance

Production up to approx. 200mm x 200mm x 200mm

CNC-controlled 3-axis machining center

CNC-controlled 3-axis machining center (yes, twice – because precision matters!)

Manufacturing in all common materials – including free-cutting steel, stainless steel, structural steel, aluminum, brass, and plastics (mainly POM)

Falz & Kannenberg

Our Expertise – Your Advantage

Why We’re Your Go-To Partner for Turning & Milling Parts

Fast Quote Turnaround

High Flexibility & Expert Consultation

Short & Reliable Lead Times

Top-Notch Quality Assurance

125+ Years of Experience & Expertise

Reliability & Trust

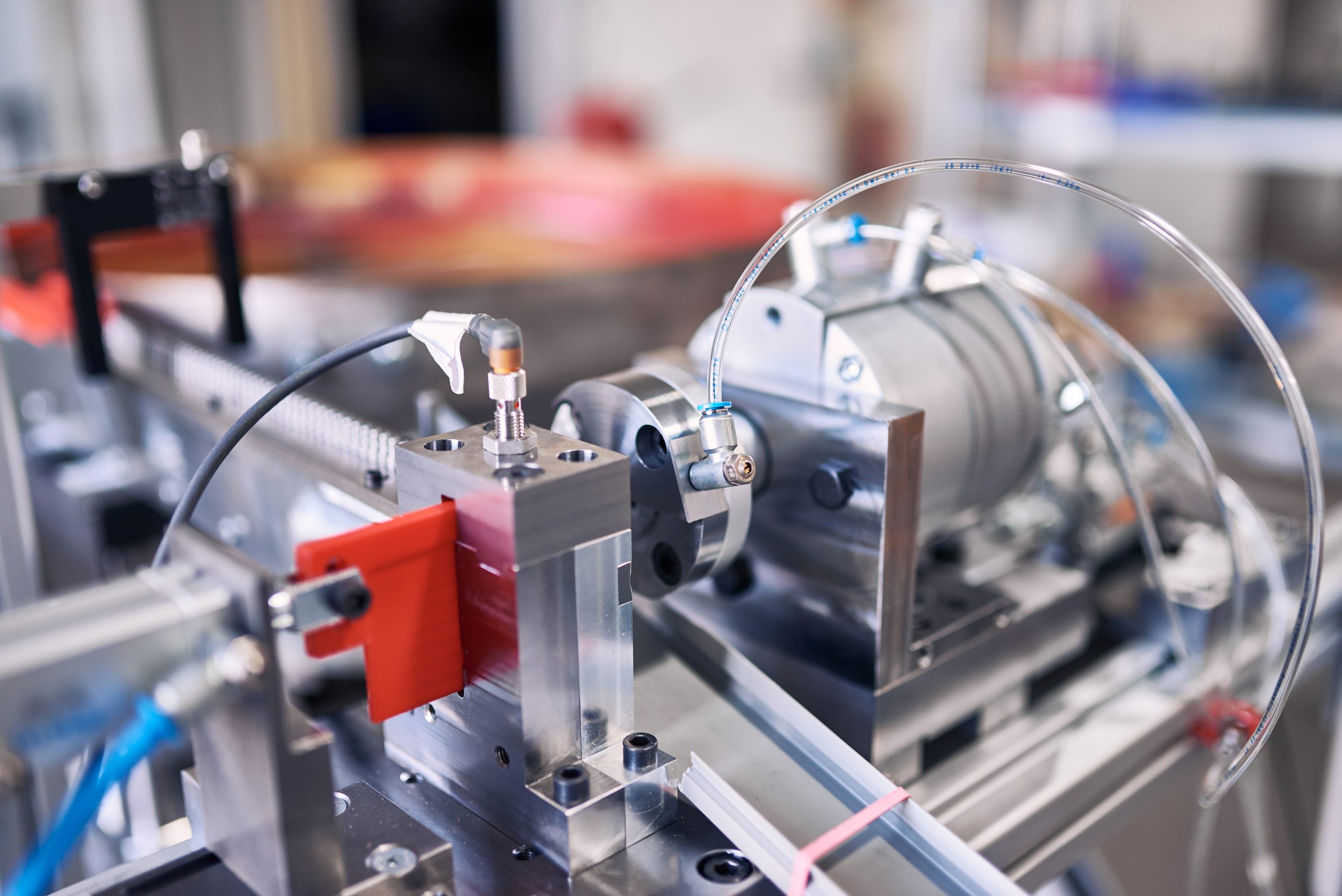

A Picture is Worth a Thousand Words

A small selection of our work.

References

Turning Parts & Milling Parts

1899

SINCE 1899 MADE IN SAXONIA

So That You Know What to Expect

Pricing at Falz & Kannenberg

3 Calculation Examples

In our industry, every cent counts.

And of course, you’d like to have a rough idea of the investment required for your turning or milling parts before requesting a quote.

That’s why we’ve put together 3 sample calculations for you!

Along with all our other advantages—fast delivery, small batch sizes, and more—you now get even more transparency in pricing.

Simply enter your details and receive the PDF with pricing examples via email!

Request your download

And this is how we work together

Fast. Simply. Transparent.

And always on time delivery.

Send drawing

Receive offer within 3 days

Accept offer

Get delivered on the desired date

Of course, we guarantee perfect product quality. But that’s what you expect from professionals who have been on the market since 1899 and whose slogan is “Perfection in detail”.

FAQ Falz & Kannenberg

Frequently Asked Questions

What types of parts can we manufacture?

For milled parts, we handle sizes up to 200mm x 200mm x 200mm. We offer both 5-axis and 3-axis milling.

What materials do we work with?

We process a variety of materials, including:

✔ Free-cutting steel (with and without lead)

✔ Structural steels (e.g., St37, St52)

✔ Alloy steels (e.g., 42CrMo4V, 16MnCr5)

✔ Aluminum (e.g., EN AW 2007, EN AW 5083, EN AW 6060, EN AW 6082, and occasionally EN AW 7022 & EN AW 7075)

✔ Stainless steel (e.g., 1.4301, 1.4305, 1.4404, 1.4571)

✔ Brass (e.g., CuZn40Pb3, CuZn39Pb2)

✔ Other alloys (upon availability)

What are our typical batch sizes?

For milling, we typically produce between 20 and 200 pieces per batch.

Do we produce single parts?

Do we deliver ready-to-install parts?

How long does delivery take?

Our standard lead time is 3 to 4 weeks, but this may extend during peak periods. Additional processes affect lead times:

- Zinc plating → +1 week

- Hardening → +1 to 3 weeks (depending on the method)

- Annealing → +1 week

- Other finishing (lapping, grinding, bead blasting, powder coating, Molycote coatings, etc.) may take longer.

What machines do we use?

- 8 Swiss-type lathes (Ø 4mm – 16mm, bar-fed)

- 10 turret lathes (Ø 6mm – 120mm, depending on the manufacturer)

Get our full machine list by entering your email and downloading the PDF.

How can you reach us?

Phone: Monday to Friday, 8 AM – 3 PM at +49 34292 862990

Email: We respond quickly at info@falzundkannenberg.de

How can you pay?

Are we certified?

Do we offer initial sample inspections?

How can you request a quote?

For a fast quote (1-3 days), please provide:

- A complete technical drawing of the part

- A 3D model in .stp format (for accurate cost calculation)

How can you place an order?

Orders can be sent via email to bestellungen@falzundkannenberg.de.

You can either:

- Write the details directly in the email

- Attach a PDF with your order information

Where do we ship?

We deliver throughout Germany and across Europe, as long as the location is truck-accessible.

Have more questions? Reach out to us!

Contact

Address

Falz und Kannenberg GmbH & Co. KG

Gewerbeallee 13

04821 Brandis, Deutschland